DOWNSTREAM POWER GENERATION OF PYROLYSIS GASES.

DOWNSTREAM POWER GENERATION OF PYROLYSIS GASES.

Technology description of downstream power generation.

By downstream power generation (electricity generation from residual materials), our customers have the advantage of using the energy generated from pyrolysis for their own CHP system as well as feeding it profitably into the grid as an additional sales channel. Green electricity is a very solid end product that remains constant in value and acts as an additional source of income.

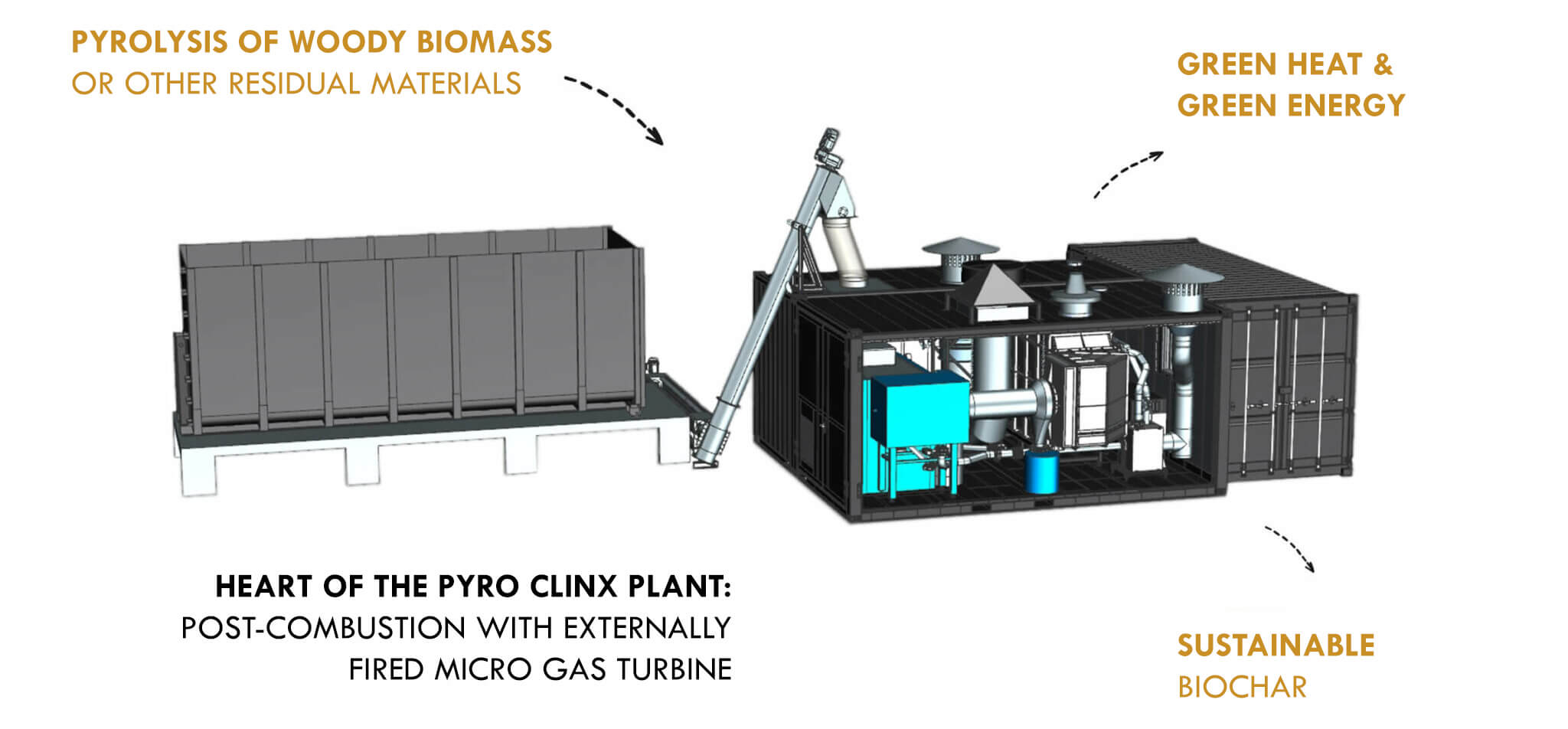

The downstream power generation of pyrolysis gases into electricity using an externally fired microturbine is an innovative technology that makes it possible to generate valuable energy from organic waste products. The use of microturbines can significantly increase the efficiency of downstream power generation, resulting in a higher energy yield and more effective use of resources.

The conversion of pyrolysis gases into electricity using an externally fired micro gas turbine consists of several technical steps:

First, the pyrolysis gas is produced by a pyrolysis plant. This is a process in which organic waste materials such as wood, straw or biomass are broken down at high temperatures and without access to oxygen. This produces a gas mixture of carbon monoxide, hydrogen, methane and other hydrocarbons.

The pyrolysis gas produced is then burned in a burner to generate the thermal energy required to operate the externally fired microturbine. The combustion capacity and temperature must be precisely matched to the requirements of the microturbine. The pyrolysis gas is now fed into the externally fired microturbine. There it is further heated by the combustion of the fuels and drives the turbine.

The kinetic energy of the gas is converted into electrical energy, which is then fed into the power grid. In summary, it can be said that the conversion of pyrolysis gases into electricity using an externally fired micro gas turbine is an efficient process for generating energy from organic waste products. However, precise coordination of the combustion capacity, temperature and exhaust gas management is necessary to ensure maximum efficiency and environmental compatibility of the process.

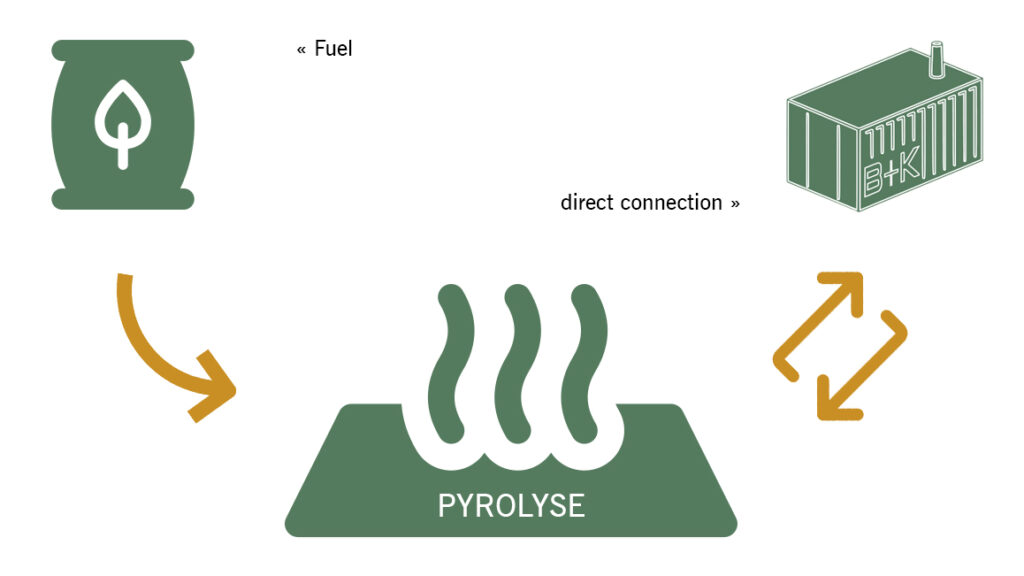

INTEGRATED DOWNSTREAM POWER GENERATION

The downstream power generation system is coupled directly with the pyrolysis system via the hot waste heat.

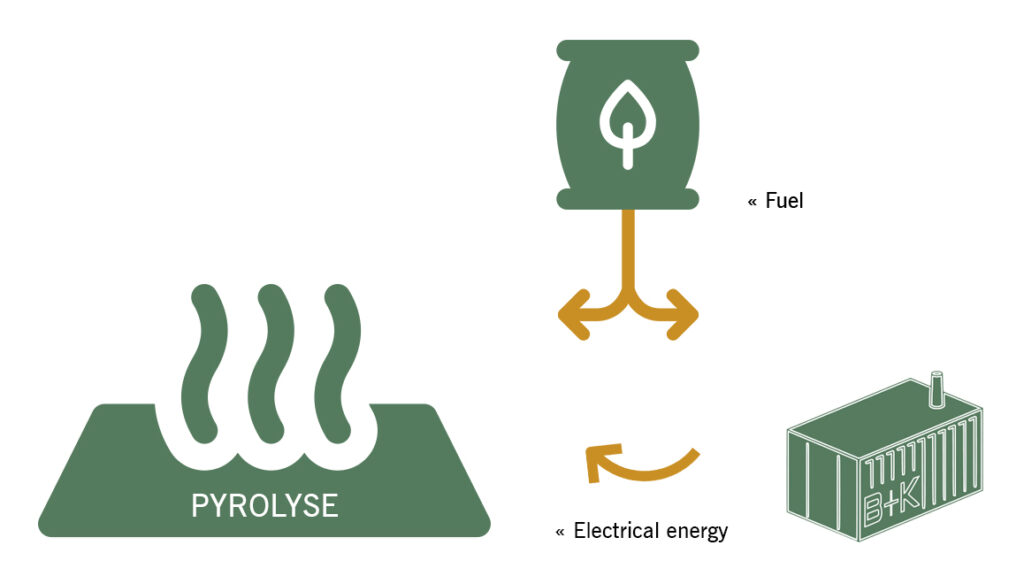

SEPARATE DOWNSTREAM POWER GENERATION

The downstream power generation of pyrolysis gases is operated separately from the pyrolysis system and provides the required electrical energy.

PROCESS DESCRIPTION - PYROLYSIS DOWNSTREAM POWER GENERATION

1) The clean ambient air compressed in the compressor is passed through the heat exchanger and heated to the required turbine inlet temperature.

2) After the hot air has expanded in the turbine, it is used as pre-process heat.

3) After a heat sink, the externally fired micro gas turbine can be connected downstream and generate electricity from the waste heat.

By using an additional power generation system, the energy production costs can be kept constant in the long term and the entire system can be supplied with green energy generated in-house. This ensures long-term economic strengthening for your company. The power generation system is a central component of our pyrolysis park »