HEAT ENERGY FROM PROCESS HEAT AND WASTE HEAT

HEAT ENERGY FROM PROCESS HEAT OR WASTE HEAT

ClinX HEAT Energy - solution for green energy from process heat and waste heat!

ClinX HEAT Energy - your solution for green energy from process heat and waste heat!

Use ClinX Heat energy from process heat and waste heat and reduce your energy costs: With the award-winning ClinX HEAT technology from pyropower GmbH, companies can tap into the potential of unused process heat or waste heat for sustainable and economical energy generation. At the heart of ClinX HEAT are the high-temperature heat exchanger and the externally fired micro gas turbine, which efficiently converts waste heat from industrial and commercial processes into electricity and heat. This innovative solution not only conserves resources, but also significantly reduces CO₂ emissions – without the use of fossil fuels. The technology offers a climate-friendly, decentralized energy supply and creates a robust energy concept aimed at sustainability and cost reduction.

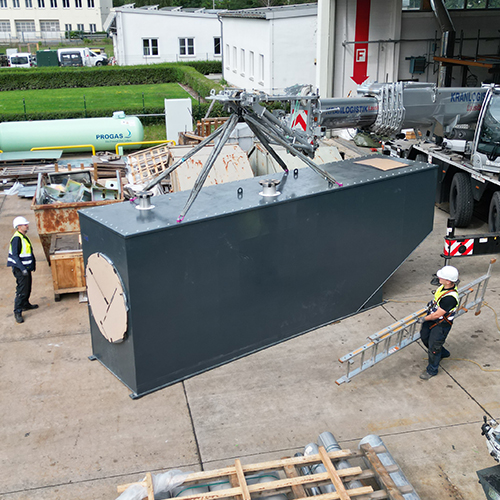

At the heart of ClinX HEAT Energy: the externally fired micro gas turbine and the high-temperature heat exchanger

Difference between process heat and waste heat

Process heat refers to the energy required in industrial or commercial processes to produce, modify or process materials, such as casting, hardening or drying. It is actively generated and used specifically in production processes. Waste heat, on the other hand, is the unused heat that is a by-product of various industrial activities. This heat is usually generated by systems or combustion processes and is often used as an additional resource in the form of energy instead of being released unused into the environment.

Cost-efficient, sustainable and CO₂-saving - your benefits with ClinX HEAT

Cost-efficient, sustainable and CO₂-saving - your benefits with ClinX HEAT

Cost reduction through internal energy

Waste heat becomes a valuable resource and significantly reduces energy costs. Unused energy, for example from production processes, can be efficiently converted by ClinX HEAT and reused as green electricity and green heat. This not only protects the environment, but also reduces dependence on rising energy costs.

Significant CO₂ reduction

By converting process or waste heat into electricity and heat, the use of fossil fuels is reduced, which lowers your company’s CO₂ emissions. The innovative process makes optimum use of existing waste heat and thus contributes, for example, to meeting your or the authorities’ climate-related targets.

NO ADDITIONAL SYSTEMS REQUIRED

ClinX HEAT enables decentralized, energy-efficient waste heat recovery without the need for additional heat generation systems. The technology (as in the Pyro-ClinX energy system, for example) is integrated directly into existing systems and optimizes your energy use without great expense and high investments in new systems.

ENERGY SELF-SUFFICIENCY AND SECURITY OF SUPPLY

Your company is independent of energy price fluctuations and you can rely on a secure energy supply. Security of supply is increased through the use of existing waste heat sources, which makes ClinX HEAT particularly interesting for energy-intensive industries.

How ClinX HEAT Energy works

How ClinX HEAT works

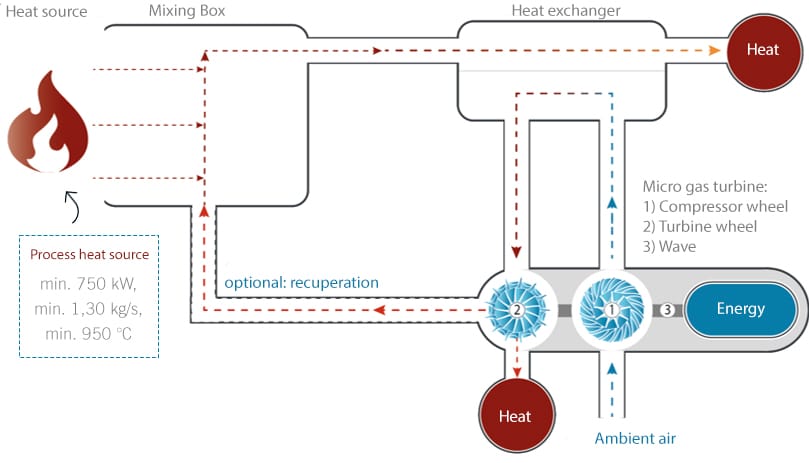

Electricity from waste heat generated by the externally fired micro gas turbine:

» Flexible integration: Can be connected to any heat source that meets minimum requirements.

» High temperature: Uses process gas at around 950 °C, which is compressed and heated in a high-temperature heat exchanger.

» Power generation: Heated air flows to the micro gas turbine and is converted into mechanical energy.

» Closed system: Exhaust gases are recirculated, which increases overall efficiency.

Process air recirculation to increase efficiency:

» Recuperation: Recirculation of the warm turbine exhaust air into the heat circuit maximizes efficiency.

» Continuous heat cycle: Without fossil fuels, ensures a constant energy supply.

» Air compression: Filtered ambient air is compressed and heated by the heat exchanger.

»Electrostatic precipitator: Ensures clean exhaust gases and protects the ambient air.

Customization and expandability:

» Modularity: Flexibly adaptable to different processes.

» Versatility: Suitable for supplying heat or generating electricity from waste heat.

» Scalability: Offers independence from fluctuating energy prices and enables efficient use of waste heat.

» Further (technical) information can be found at any time in the data sheet – for download «

ClinX HEAT - For green process heat and industrial applications

In the (retail) trade, commerce and services sectors, a large proportion of total final energy consumption is used for heating and cooling. Especially for industrial applications such as hardening, casting, firing or drying processes, the recovery and use of process heat is crucial. The waste heat from these processes often remains unused, although it offers enormous potential for energy savings. ClinX HEAT tackles this problem and closes the gap between energy use and energy generation by efficiently converting process heat or waste heat into renewable energy.

Advantages of a ClinX HEAT combination with pyrolysis processes

Advantages of a ClinX HEAT combination with pyrolysis processes

ClinX HEAT can easily be combined with a pyrolysis process, such as the Pyro-ClinX system, to further increase energy yield and efficiency. Pyrolysis processes generate valuable pyrolysis gases from organic residues, which can be additionally utilized by ClinX HEAT. This combination offers advantages such as

✔ Optimized efficiency through the use of residual materials and the generation of green electricity and heat

✔ Circular economy and CO₂ reduction by effectively integrating waste products into energy generation

✔ Scalability and flexibility, as the modules can be individually adapted to your needs and implemented decentrally

Thanks to this modular combination of waste heat and pyrolysis process, such as the carbonization plant in Darmstadt Pyro-ClinX pyrolysis plant, the energy potential can be exploited even more intensively and converted into CO₂-neutral added value. Companies receive an energy-efficient 360° complete solution that increases their added value and protects the environment.

Companies receive an energy-efficient 360° complete solution that increases their added value and protects the environment. Rely on ClinX HEAT and embark on a sustainable, cost-efficient energy future! For detailed information and individual advice: contact us today and turn your process heat and waste heat into the energy source of the future!