SUSTAINABLE PYROLYSIS SYSTEM PYRO-CLINX.

SUSTAINABLE PYROLYSIS SYSTEM PYRO-CLINX.

PYROLYSIS PLANT PYRO-CLINX. LIGHTHOUSE PROJECT FOR DECARBONIZATION.

PYROLYSIS PLANT PYRO-CLINX. LIGHTHOUSE PROJECT FOR DECARBONIZATION.

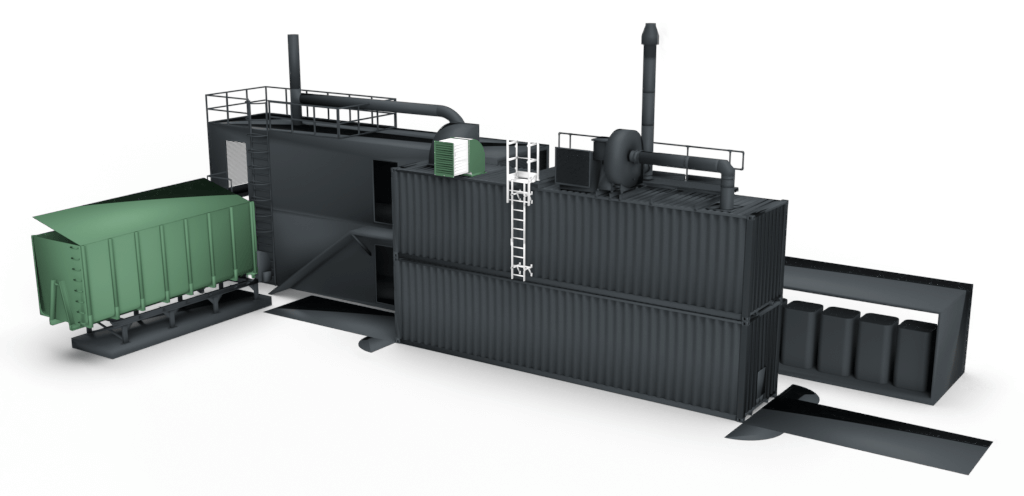

The technology we use is proven technology – in a unique, innovative combination! We combine a pyrolysis process with an externally fired micro gas turbine to generate electricity. The combination of pyrolysis system and ClinX creates “Pyro-ClinX” – a self-sufficient, sustainable, CO2-neutral pyrolysis system.

#Letsgetgreen. We are designing a regenerative pyrolysis plant with green downstream power generation that is tailored to the specific requirements of our wide range of customers: from energy generation from green electricity to efficient sewage sludge disposal and the production of sustainable biochar. CO2-neutral production of a CO2-negative product – making a sustainable contribution to climate change. Our credo: We want to be self-sufficient in the future. Our pyrolysis plant supplies itself with the energy converted on site (heat and electricity). We are certain that the “Pyro-ClinX plant park” will be a beacon project for decarbonization.

Product information Pyrolysis CHP Pyro-ClinX 150

*Note: The specified performance values refer to standard design conditions (ambient temperature: 15 °C, relative humidity: 80 %, altitude: sea level). The actual output may vary due to factors such as ambient conditions, heat sink and operating mode. The specific output is calculated taking into account the individual site conditions as part of the project planning.

Pyrolysis.

The concept is a combination of pyrolysis plant and CHP system (ClinX). In the pyrolysis process, the woody residues are carbonized in the absence of air, thus producing biochar. The process is similar to the natural formation of coal, but is extremely shortened in terms of time. The heat generated during the pyrolysis process is sustainably converted into electricity using the ClinX CHP system. In this way, the system provides both its own energy as well as additional EEG-compliant feed-in electricity into the public grid, which can be expanded on a modular basis.

There is great untapped potential in the area of solid biogenic residues. The total residue potential of dry substrate in Germany is 151.1 million tons, of which around a third remains unused to date.

This applies in particular to wood and forestry residues as well as agricultural by-products, for which there have hardly been any marketing opportunities to date.

The reason for this is that the materials have very heterogeneous properties and cannot be converted into energy by conventional systems. In addition, the materials usually accumulate decentrally, meaning that their centralized recycling or disposal is associated with high transport and logistics costs.

Our plant concept focuses on the biomasses of forest residues, industrial residues, landscape conservation wood and damaged wood.

DOWNSTREAM POWER GENERATION AND HEAT UTILIZATION!

Pyro-ClinX uses waste heat from the pyrolysis process to maximize its efficiency and sustainability. This environmentally friendly energy system converts the resulting process heat into electrical energy using a powerful externally fired micro gas turbine. This makes it a reliable solution for generating CO2-neutral green electricity.

The high-temperature heat exchanger, which we developed ourselves, is the heart of the system. It heats the intake air to up to 850°C and uses the thermal energy to generate electricity without any losses. The process waste heat is also used intelligently in addition to post-conversion: it is used to dry biomass streams that serve as fuel for the system. In this way, it makes full use of the energy potential of our systems. This integration makes it possible to produce up to 1 million kWh of green energy per year – a truly profitable solution for the environment!

Fuel flexible

Pyro-ClinX enables the pyrolysis of various residual materials and therefore offers a wide range of fuels. In principle, wood from various sources can be used, such as forest and industrial waste wood as well as wood from landscape conservation. Biogenic waste streams such as fermentation residues, sewage sludge and screen overflows are also conceivable. On the fuel side, the necessary requirements for the desired certification must be observed, e.g. only forest wood from sustainable forestry may be used for EBC certification (European Biochar Certificates | European Biochar Certificate).

Decentral

Pyro-ClinX can be operated decentrally close to the source of fuel. This reduces the logistical effort and costs of fuel transportation. The locations can thus be optimally positioned according to the ratio of suppliers and customers.

Modular

The modular system adapts to new production processes or changes in the composition of the material flows. Pyrolysis modules can be added as required, and the ClinX CHP modules can also be expanded. The system can also be expanded in a user-oriented manner: a cold generation, water treatment or ORC (Organic Rankine Cycle) module can be added as required.

Robust/ low maintenance

Due to the externally fired micro gas turbine, the flue gases are not fed directly to the micro gas turbine. This works exclusively with clean and filtered ambient air, which is heated indirectly via the heat exchanger. This system characteristic enables fuel-independent, low maintenance costs. The air-bearing turbine also works exclusively with air and requires no lubricants or coolants. Pyro-ClinX therefore offers a robust and low-maintenance system.

Reliable supply

Independence from central power supply and rising energy prices – Pyro-ClinX operates as an energy self-sufficient system. The system is therefore independent of rising energy market prices and has clear advantages over other biochar production systems in terms of its own production price stability.

Resource efficient

Pyro-ClinX is a combined heat and power system. The thermal efficiency from the pyrolysis process is supplemented by efficient electrical generation. Due to the robust design and long service life of the system, the materials used in the system itself are also used as efficiently as possible.

Eco-friendly

Energy conversion from renewable energy sources replaces energy conversion from fossil energy sources. This renewable energy generation contributes to CO2 savings and climate protection. The system is energy self-sufficient and uses a CO2-neutral CHP process. In addition, CO2 is bound in the biochar, thus producing a CO2-negative product. It goes without saying that the high German air pollution control standards are complied with. Furthermore, a decentralized solution reduces the transport volume and the associated CO2 and pollutant emissions.

Economical

The plant supplies itself with the necessary energy from its own process and thus offers a production cost advantage for the pyrolysis coal. Surplus electricity can be fed in profitably with EEG subsidies. Due to the wide range of input materials, low-cost input materials can be used and residual materials in the immediate vicinity can be converted into energy.